WEB Catalog

Product List

- Air Management System

-

Directional Control Valves

- Pilot Operated 4/5 Port Solenoid Valves

- Pilot Operated 3 Port Solenoid Valves

- Direct Operated 3/4/5 Port Solenoid Valves

- Reduced-wiring Fieldbus System (Serial Transmission System)

- Wireless System

- Air Operated Valves

- Mechanical Valves/Transmitters

- Finger Valve/Hand Valves/Residual Relief 3 Port Valve

- Blow Guns

- Power Valves

- ISO Valves

- Explosion-Proof Valves

- Pilot Operated 4/5 Port Solenoid Valves

-

Air Cylinders

- Standard Air Cylinders (Round Type)

- Standard Air Cylinders (Square Cover)

- Compact Air Cylinders

- Environment Resistant Cylinders

- Floating Joints/Rod End

- Air-hydro Units

- Mechanically Jointed Rodless Cylinders

- Magnetically Coupled Rodless Cylinders

- Table Cylinders

- Guide Cylinders

- Dual Rod Cylinders

- Lock Cylinders/Cylinder with An End Lock

- Fine Lock Cylinders

- Specialty Cylinders

- Clamp Cylinders

- Pin Shift Cylinder

- Stopper Cylinders

- Stroke Reading Cylinders

- Valve Mounted Air Cylinders

- ISO Cylinders: ISO Standards (6432)

- ISO Cylinders: ISO Standards (15552)

- ISO Cylinders: ISO Standards (21287)

- ISO Cylinders

- Shock Absorbers

- Auto Switches

- Wireless Auto Switches

- Actuator Position Sensor

- Flow Control Equipment

- Standard Air Cylinders (Round Type)

- Rotary Actuators/Air Grippers

-

Electric Actuators/Cylinders

- e-Actuator

- Manifold Controller/Manifold Controller Compatible Electric Actuator

- Battery-less Absolute Encoder Type

- Slider Type

- Rod Type/Guide Rod Type

- Slide Tables

- Miniature

- Rotary Tables

- Grippers

- Grippers for Collaborative Robots

- Controllers/Drivers

- Environment

- Motorless Type

- Mounting Kit for Multi-Axis System

- Electric Cylinders

- Card Motor

- Teaching Box

- Made to Order

- e-Actuator

-

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other)

- Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems

- Vacuum Ejectors

- Vacuum Gripper System (Foam Type)

- Vacuum Release Valve Units

- Air Suction Filters

- Vacuum Pads (Vacuum Suction Cups)

- Special Pads

- Gripper for Collaborative Robots

- Vacuum Saving Valves

- Magnet Buffer

- Vacuum Flow

- Vacuum Regulators

- Related Equipment for Vacuum Systems

- Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems

- Grippers for Collaborative Robots

- Compact Compressor

- Air Preparation Equipment

- Modular F.R.L./Pressure Control Equipment

- Modular F.R.L. Units

- Pressure Control Equipment

- Booster Regulators

- Lubrication Equipment

- Gas Generator

- Fittings and Tubing

-

Flow Control Equipment

- Speed Controllers for General Purposes

- Speed Controllers for Low Speed Control

- Speed Controllers Special Environments

- Speed Controllers with Special Functions

- Tool Operation Type Speed Controllers

- Air Saving Speed Controllers Air Saving Valves

- Remote control valve (Electric speed controller)

- Related Equipment

- Speed Controllers for General Purposes

- Silencers/Exhaust Cleaners/Pressure Gauges

- Air Blowing Equipment

-

Switches/Sensors/Controller

- Electronic Pressure Switches/Sensors (Self-contained Type)

- Electronic Pressure Switches/Sensors (Remote Type)

- Mechanical Pressure Switches

- Electronic Flow Switches/Sensors

- Clamp-on Type Flow Sensor

- Mechanical Flow Switches

- Air Management System

- Controllers

- Electronic Temperature & Humidity Switches

- Auto Switches for Air Cylinders

- Auto Switches for Rotary Actuators and Air Grippers

- Position Sensor

- Electronic Pressure Switches/Sensors (Self-contained Type)

-

Static Neutralization Equipment

- Static Neutralization Equipment Ionizer Bar Type

- Static Neutralization Equipment Nozzle Type Ionizer

- Static Neutralization Equipment Fan Type Ionizer

- Static Neutralization Equipment Ionizer Gun

- Static Neutralization Equipment Desktop Duster Box

- Static Neutralization Equipment Electrostatic Sensor/Sensor Monitor/Meter

- Static Neutralization Equipment/Ionizers

- Static Neutralization Equipment Ionizer Bar Type

-

Industrial Device Communication Equipment/Wireless System

- Wireless System: PROFINET Compatible Products

- Wireless System: EtherNet/IP Compatible Products

- Wireless System: EtherCAT Compatible Products

- Wireless System: IO-Link Compatible Products

- Wireless System: CC-Link Compatible Products

- Wireless System: DeviceNet Compatible Products

- Industrial Device Communication Equipment: PROFINET Compatible Products

- Industrial Device Communication Equipment: EtherNet/IP Compatible Products

- Industrial Device Communication Equipment: EtherCAT Compatible Products

- Industrial Device Communication Equipment: Modbus TCP Compatible Products

- Industrial Device Communication Equipment: ETHERNET POWERLINK Compatible Products

- Industrial Device Communication Equipment: CC-Link IE Field Compatible Products

- Industrial Device Communication Equipment: SSCNET III Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅲ Compatible Products

- Industrial Device Communication Equipment: PROFIsafe Compatible Products

- Industrial Device Communication CIP Safety Compatible Products

- Industrial Device Communication Equipment: IO-Link Compatible Products

- Industrial Device Communication Equipment: PROFIBUS Compatible Products

- Industrial Device Communication Equipment: DeviceNet Compatible Products

- Industrial Device Communication Equipment: CC-Link Compatible Products

- Industrial Device Communication Equipment: AS-interface Compatible Products

- Industrial Device Communication Equipment: CompoNet Compatible Products

- Industrial Device Communication Equipment: Interbus Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅱ Compatible Products

- Other: RS232C Compatible Products

- Other: RS485 Compatible Products

- Wireless System: PROFINET Compatible Products

- Process Valves

- Chemical Liquid Valves/Fittings & Needle Valves/Tubing

- Process Pumps(Diaphragm Pumps)

-

Temperature Control Equipment

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Dual Channel Thermo chiller for Lasers

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

- Chiller Compliant Regulations

- Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

- Air Temperature Controllers

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

- Process Gas Equipment AP Tech

- High Vacuum Equipment

- Industrial Filters/Sintered Metal Elements

- Pneumatic Instrumentation Equipment

- Hydraulic Equipment

Theme

-

Clean Series/Low-Particle Generation

- Directional Control Valves

- Air Cylinders

- Rotary Actuators

- Air Grippers

- Air Dryers

- Compressed Air Cleaning Filter Series

- Clean Gas Filters/Air Filters

- Exhaust Cleaner for Clean Room/Clean Exhaust Filter

- Modular F.R./Pressure Control Equipment

- Fittings

- Tubing

- Flow Control Equipment

- Switches/Sensors

- Flow Switch

- Electric Actuators

- Directional Control Valves

- Fluoropolymer Equipment/PVC Equipment

-

Series Compatible with Secondary Batteries Series 25A-

- Air Management System

- Directional Control Valves

- Wireless System

- Actuators

- Related Products

- Rotary Actuators/Air Grippers

- Vacuum Equipment

- Air Preparation Equipment/Clean Air Filters

- ModularF.R.L./Pressure Control Equipment

- Flow Control Equipment/Fittings

- Tubings

- Detection Switches/Auto Switches

- Static Neutralization Equipment/Ionizers

- Process Valves

- Process Gas Equipment

- Electric Actuators

- Air Management System

- Copper, Fluorine-free Equipment Series 20-

- ISO Products

- Arc Welding Process Equipment

- IO-Link Compatible Products

- Grease-free Nitrogen (N2) Compatible Equipment

- List of ATEX Compliant Products

- Explosion-Proof Valves Certified Products

- Equipment for the Food Manufacturing Industry

- Equipment for the Semiconductor Industries

-

Equipment for the Semiconductor Industries (Temperature Adjustment Line)

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

- Chiller Compliant Regulations

- Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

Air Blowing Equipment

Blow Gun

VMG

OSHA Standard Compliant Nozzle for One-touch Fitting

KNA(G)-Q10-180

Nozzles for Blowing

KN

Wide Angle Blow Nozzle

IN-225

Air Saving Impact Blow Gun

IBG

Pulse Blow Unit

PU

Ionizer Gun

IZG10

Air Saving Impact Blow Valve

IBV

Pulse Blow Valve

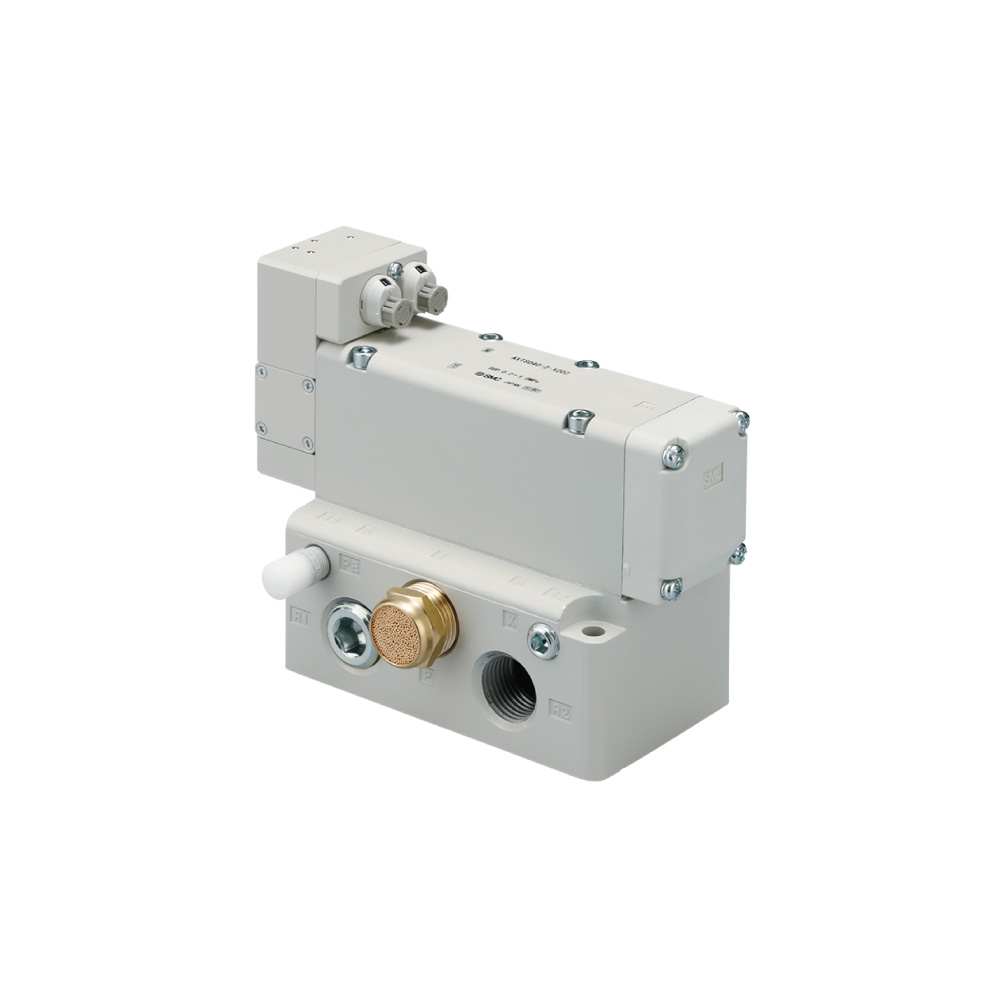

AXTS040-X202

Pulse Blow Valve

AXTS040□-□□-X2

Vacuum Flow

ZHV

Vacuum Flow Stainless Steel Specifications

ZH□-□-X341

Vacuum Flow

ZH-X226/-X249/-X338

List

List Picture

Picture